Class 40 Gray Iron

Atlas carries

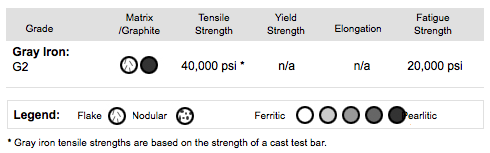

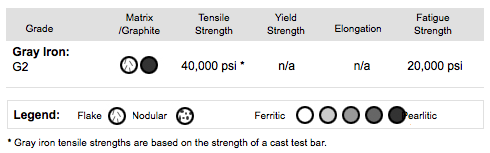

G2, CLASS 40 GRAY IRON. It is a pearlitic gray iron containing Type A graphite. Gray Iron bars

made to this specification have optimal strength, wear and hardness when

compared to the other gray iron grades. This material is well suited

for applications requiring high resistance to wear and response to heat

treatment. This specification is similar to ASTM A48 class 40.

Click on the below image to select your size:

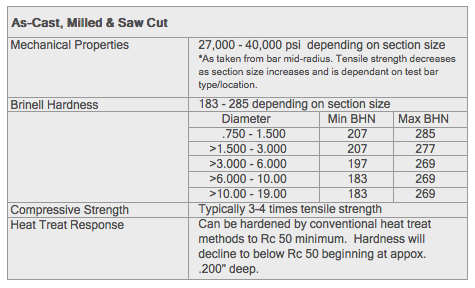

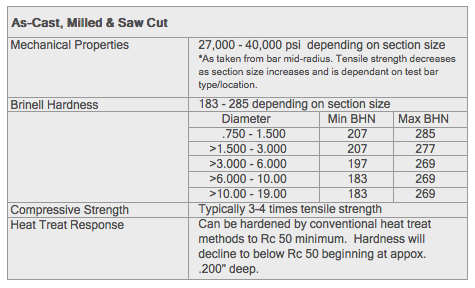

Class 40 Gray Iron Heat Treatment Response:

G2 Gray Iron can be hardened by fast methods, such as flame and induction

hardening, in addition to conventional quench and temper methods.

G2, ASTM A48 Class 40 Gray Iron can be oil quench hardened from 1600° F (885° C) to a minimum hardness of Rockwell C 50 on the outside of the bar. The inside diameter

hardness will be less than Rockwell C 50. Lower quench hardness on the

inside diameters are a result of larger graphite flakes and not as loss

of matrix hardness. Typical Jominy end quench test data are shown in the

section on Heat Treating.

Class 40 Gray Iron Microstructure:

The microstructure will contain Type VII, A, size 4-6 graphite as defined

in ASTM A247. The matrix is fully pearlitic. The rim will consist of

Type D, size 4-6 graphite in a pearlite matrix with small amounts of

ferrite. Chill carbides will be less than 5% in any field at 100x and

are well dispersed.

Class 40 Gray Iron Specifications:

|