Oil & Grease Groove Bronze Bushings

Our Cast Bronze Bushings are machined from continuous cast C93200 (SAE 660)

bronze for superior quality and performance. The continuous casting

process assures a uniform bronze structure throughout the bearing, free

from porosity and hard particle inclusions commonly found in other cast

processes.

Our standard bronze bushing line features over 1,000 sizes that are

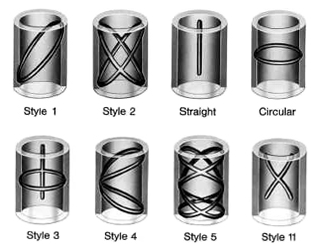

carried in stock. Any of our standard stock sizes of Sleeve Bushings are adaptable to grooving and graphite plugging. You select your desired size and we add the lubricant of your choice. Unless otherwise specified, the width and depth of the oil grooves will be proportional to the wall thickness and size of the bearing, contained within the bearing.

Note:

In order to form a more perfect oil film between the bearing &

shaft, we recommend a V-shaped groove whenever the design permits, as it

allows full flow of the lubricant across the bearing surface.

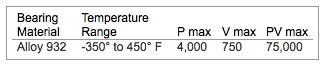

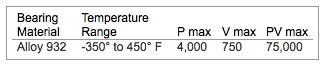

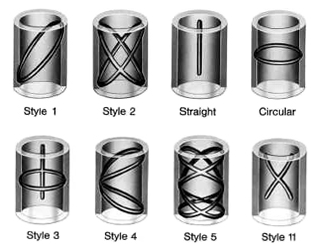

1.) Choose your Bronze Bushings Style:

2.) Choose your Bronze Bushing Size:

C93200 CHEMICAL COMPOSITION:

(%max., unless shown as range or min.)

NOTE: Information courtesy of Copper.org

|

Cu(1)

|

Al

|

Sb

|

Fe

|

Pb

|

Ni(2)

|

P(3)

|

Si

|

S

|

Sn

|

Zn

|

|

Min./Max.

|

81.0-85.0

|

.005

|

.35

|

.20

|

6.0-8.0

|

1.0

|

.15

|

.005

|

.08

|

6.3-7.5

|

1.0-4.0

|

|

Nominal

|

83.0

|

-

|

-

|

-

|

7.0

|

-

|

-

|

-

|

-

|

6.9

|

2.5

|

(1) In determining Cu min., Cu may be calculated as Cu + Ni.

(2) Ni value includes Co.

(3) For continuous castings, P shall be 1.5%, max.

Note: Cu + Sum of Named Elements, 99.0% min.

C93200 MECHANICAL PROPERTIES:

(measured at room temperature, 68 F (20 C)

NOTE: Information courtesy of Copper.org

|

Temper

|

Section

Size

|

Cold

Work

|

Typ/

Min

|

Temp

|

Tensile

Strength

|

Yield

Strength

(0.5% ext.

under load)

|

Yield

Strength

(0.2%

offset)

|

Yield

Strength

(0.05%

offset)

|

El

|

Rockwell

Hardness

|

Vickens

Hard.

|

Brinell

Hard.

|

Shear

Strength

|

Fatigue

Strength*

|

Izod

Impact

Strength

|

|

in.

|

%

|

|

F

|

ksi

|

ksi

|

ksi

|

ksi

|

%

|

B

|

C

|

F

|

30T

|

500

|

500

|

3000

|

ksi

|

ksi

|

ft-lb

|

|

mm.

|

|

|

C

|

MPa

|

MPa

|

MPa

|

MPa

|

|

|

|

|

|

|

|

|

MPa

|

MPa

|

J

|

|

As Sand Cast

|

|

M01

|

0.0

|

0

|

TYP

|

68

|

35

|

18

|

-

|

-

|

20

|

-

|

-

|

-

|

-

|

-

|

65

|

-

|

-

|

16

|

6.0

|

|

0.0

|

|

|

20

|

241

|

124

|

-

|

-

|

20

|

-

|

-

|

-

|

-

|

-

|

65

|

-

|

-

|

110

|

8.0

|

|

As Centrifugal Cast

|

|

M02

|

0.0

|

0

|

SMIN

|

68

|

30

|

14

|

-

|

-

|

15

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

|

0.0

|

|

|

20

|

207

|

97

|

-

|

-

|

15

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

|

As Continuous Cast

|

|

M07

|

0.0

|

0

|

SMIN

|

68

|

35

|

20

|

-

|

-

|

10

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

|

0.0

|

|

|

20

|

241

|

138

|

-

|

-

|

10

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

|

As Sand Cast

|

|

M01

|

0.0

|

0

|

SMIN

|

68

|

30

|

14

|

-

|

-

|

15

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

|

0.0

|

|

|

20

|

207

|

97

|

-

|

-

|

15

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

0.0

|

*Fatigue Strength: 100 x 10 6cycles,

unless indicated as [N]X 106.

C93200 APPLICABLE SPECIFICATIONS:

NOTE: Information courtesy of Copper.org

|

Product

|

Specification

|

|

Centrifugal

|

ASTM B271

SAE J462, J461

|

|

Continuous

|

ASTM B505

SAE J461, J462

|

|

Ingot

|

ASTM B30

|

|

Permanent Mold

|

SAE J461, J462

|

|

Sand

|

ASTM B584, B763, B66

SAE J462, J461

|

|